Carbon capture and storage is a relatively new technology to store pressurized carbon dioxide underground. One of the challenges is to keep pipelines and injection tubes safe and prevent corrosion. Element supports corrosion testing of metallic components and examines polymeric materials to reduce transport costs and avoid failure.

随着二氧化碳(二氧化碳)对环境的关注增加,将碳排放减少到大气中,现在是大多数工业化国家的重点。减少碳排放导致碳捕获和储存(CCS),或碳捕获,利用和储存(CCU)项目。该项目主要是在美国和加拿大加拿大储蓄(EOR),但欧洲,亚洲和中东需求日益增长。

规划阶段的众多全球项目是在大多数国家生产CO 2的多个国家的试点,研究和开发工厂的运作。大多数CCS / CCU项目旨在捕获二氧化碳并将其存储在地面以下,主要是在海上地点。

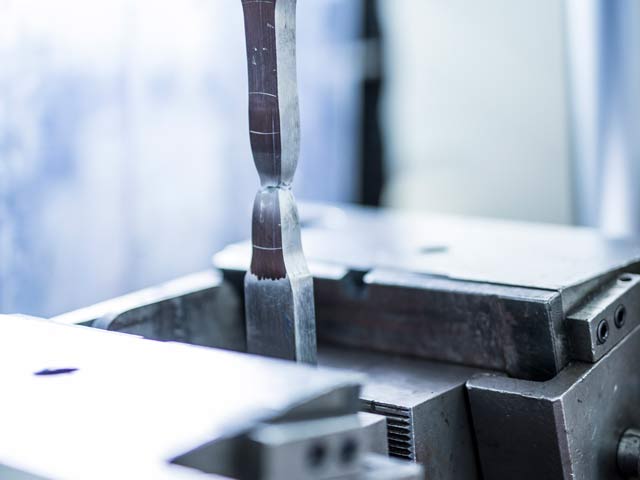

CCS运输管道的腐蚀乐动体育网址多少

对于CCS / CCUS基础设施中使用的金属,碳钢运输管道和碳钢或腐蚀合金(CRA)注射管的腐蚀或开裂是潜在腐蚀性环境的主要关注点。乐动体育网址多少

腐蚀的风险/需要evaluat开裂ed on a case-by-case basis since it’s severity will depend on the material and the specific levels of H2O, O2 and acidic gas impurities of CO, H2S, SOx, and NOx in the dense phase CO2.

为了减轻CCS运输管道中的碳钢腐蚀,使用corrosion inhibitorscan be considered. However, their effectiveness would be dependent on the specific conditions, so would require qualification testing.

Corrosion Testing for CCS infrastructure may be required to evaluate the resistance of the materials to:

- CO诱导Stress Corrosion Cracking (SCC)碳钢(运输管道)乐动体育网址多少

- H2S诱导Sulfide Stress cracking (SSC)碳钢(运输管道)乐动体育网址多少

- H2S诱导Stress Corrosion Cracking of CRA’s (Injection tubing/casing)

- 一般腐蚀碳钢(运输管道)乐动体育网址多少

- Pitting corrosionof corrosion-resistant alloys-CRA’s (Injection tubing/casing)

测试聚合物材料乐动娱乐官网

The main concerns in the use of polymeric materials for seals, linings, etc. in the CCUS infrastructure are:

- the physical effects of the CO2 on those materials, for example swelling and weakening

- rapid gas decompression damage such as blistering, cracking, splitting

- 耐化学性对气体杂质 - 污染物对材料长期完整性的影响乐动娱乐官网

- the high pressure and low temperature operating conditions for CCUS can be a limiting factor to the use of some polymers

- 通过聚合物密封和衬里渗透二氧化碳引起的产品或环境问题

元素优势

我们为能源部门的卓越中心位于美国和欧洲。该位置完全配备,以对CCS / CCUS基础设施用于CCS / CCUS基础设施的金属组分和聚合物材料进行腐蚀测试和电化学测试。乐动娱乐官网

For more information about our corrosion testing services for CCS/CCUS, or request a quote,contact us今天。

Corrosion Services

了解跨全球实验室网络的石油和天然气行业的元素大量腐蚀测试专业知识。

阅读更多

结构试验与机械工程

元素offers a range of advanced and application oriented engineering services to help solve a wide variety of mechanical engineering and structural engineering analysis problems.

READ MORE

涂料测试

了解涂料测试服务的元素范围,旨在帮助我们为客户进行测试的材料,产品和管道,免受腐蚀,紫外线,水渗透,热,磨损和化学品的保护。乐动娱乐官网

read More

Materials Testing

了解有关元素的综合材料综合材料检测服务,涵盖材料选择,应用和性能测试以及故障分析测试服务。乐动娱乐官网

阅读更多